Image Video Online Monitoring Project for Shenzhen Power Supply Bureau Transmission Line

- 2020-01-12 21:51:00

- admin Original

- 2452

Project Overview

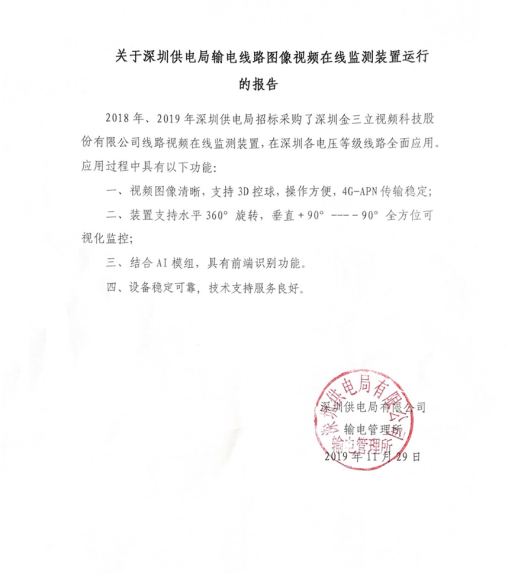

The coverage of equipment can reach 100% with Santachi V7-transmission online monitoring video device equipment, achieving China's first AI intelligent identification visual online monitoring due to the project of full coverage of video channels of Shenzhen Power Supply Bureau in 2018 and 2019.

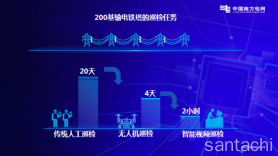

The Shenzhen Power Supply Bureau project compiled a related report for the full coverage of the video channel: Based on the inspection of 200 base transmission towers as the standard, the traditional manual inspection was shortened to 2 hours in 20 days.

Operational Report

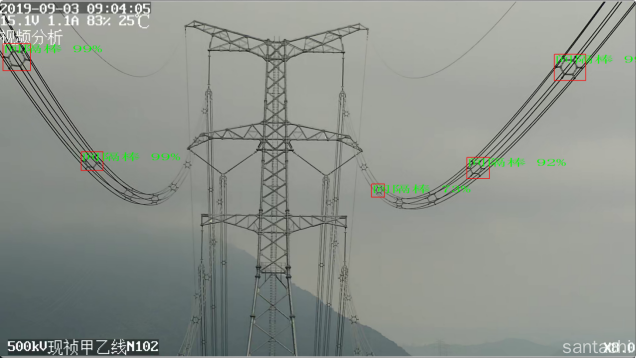

Live effect

The electric wire channel intelligent inspection device is installed on the power line tower, which can transmit the images and videos of the line corridor, channel, tower, insulators, wires, hardware, etc. to the monitoring center platform via the 4G wireless private network, supporting front-end intelligent analysis processing, conduct the remote online monitoring and alarming of places that are prone to safety hazards such as large line spans, foreign body hanging on the wire , building construction vehicles around the lines, prevention of burglary of tower, and ultra-high trees.

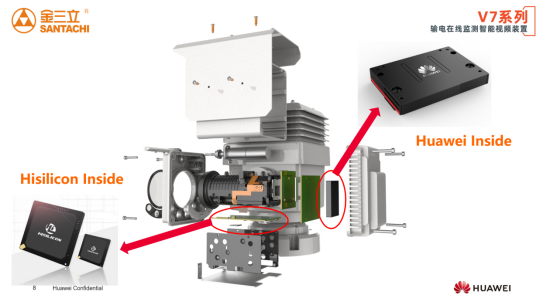

Santachi fully cooperates with Huawei to encode the Huawei Hisilicon chip in video compression in V7 products (cooperating with automation). The Huawei Atlas A200 built-in is used in the artificial intelligence calculation to implement the calculation hardware operator built-in and prepare the hardware for edge computing.

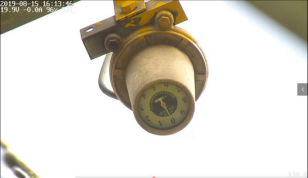

Site effect of device installation:

|

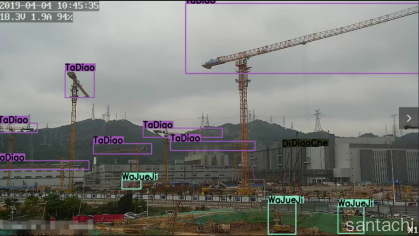

Channel monitoring display:

|

|

Great span of transmission channels | Cross the highway |

|

|

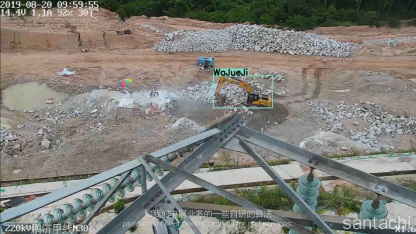

Construction Site | High incidence area of floating objects |

Foreign body monitoring display:

|

|

Hanging threat of floating objects | Nest threat |

|

|

Near-line threat of mechanical equipment | The threat from tower foundation landslide |

Hardware detail monitoring display:

|

|

|

|

|

|

Night vision effect:

Give full play to the advantages of Hisilicon and SONY chips to achieve translucent monitoring at night and 7x24 uninterrupted monitoring.

白天效果 | 夜间效果 |

|

|

|

|

Preposition intelligence analysis:

More than 2500 pole towers are 100% built-in Atlas A200 in Shenzhen Power Supply Bureau, which provides hardware conditions for edge computing. It also pioneered the remote upgrade of algorithms, which can continuously upgrade the algorithms and serve the operation and maintenance of transmission lines continuously. The Santachi deep learning algorithm is loaded to realize the identification of large excavators, cranes, pile drivers, etc. at the construction site under the transmission line. Real-time monitoring is realized, and its computing capacity can reach 15 frames per second.

|

|

|

|

Smart Line Inspection

The automatic inspection of the picture along the wire can be realized through the preset algorithm, the installation of the automatic control pan and tilt head and lens magnification. The transmission tower body can be identified and monitored through deep learning, to identify clearly the details such as Stockbridge damper, space bar and insulator. The running state of the equipment can be determined through identification. Providing reliable primary data for power operation and maintenance.

Value of customer:

At this stage, power system inspections are mainly done by human inspections and drone inspections. However, traditional human inspections rely on telescopes, consuming more human resources, have limited observation positions and long inspection cycles. UAV inspection depends on various types of aircraft, with long inspection cycles and weak endurance power. None of these methods can solve customer pain points.

The on-line monitoring device and management platform of the transmission line developed by Santachi realizes fully automatic operation and maintenance inspection, reducing operation and maintenance time from 20 days of traditional manual inspection and 4 days of drone inspection to 2 hours. At the same time, full-automatic operation and maintenance inspections can be used for accurately finding defects, improving work efficiency, reducing operational risks, and helping achieve "zero sense of power outages."

|

Achievement display for Santachi assisting Shenzhen Power Supply Bureau

The major breakthrough of the full coverage project of video channel of Shenzhen Power Supply Bureau, the intelligent video inspection, has received great attention from CCTV, and the demonstration of the project's results was completed by Monitoring Video Device of Santachi Transmission Online.

| |

|

| Phone : | 0755-83150898/0755-83151222 |

|---|---|

| Fax : | 0755-83150161 |

| Website : | www.santachi.com.cn/ |

| Address : | Santachi Building, 306 Xuegang North Road, Longhua, Shenzhen |